2. 广东美的生活电器制造有限公司, 广东 佛山 528300;

3. 佛山市顺德区美的电热电器制造有限公司, 广东 佛山 528311

2. Guangdong Midea Household Electric Appliance Manufacturing Co. Ltd., Foshan 528300, China;

3. Foshan Shunde Midea Electric Heating and Electric Appliance Manufacturing Co. Ltd., Foshan 528311, China

相变材料作为潜热储能材料在熔化和凝固过程可以储存或释放大量热量,广泛应用于太阳能储能[1]、建筑节能[2]、废热回收[3]、电力“移峰填谷”[4]等领域。相变材料按其种类可分为有机相变材料和无机相变材料,按其相变方式又可分为固-固相变材料、固-液相变材料和液-气相变材料,和固-固及液-气相变材料相比,固-液相变材料在较窄的温度范围内有较高的蓄热能力和较小的体积变化,因而实际使用更多。然而,固-液相变材料相变时液体泄漏和自身固有的低热导率问题限制了它们的应用。因此,人们提出了一些防漏方法,如多孔基质吸附[5-6]、封装[7-8]、聚合物基质复合[9-10]等方法来解决泄漏问题。另一方面,添加高导热颗粒[11-15]和高导热多孔介质吸附[16-17]可以有效提高相变材料热导率,已成为开发新型相变材料的有效策略。

生物质可以通过碳化改性成为多孔碳材料[18],这些生物质碳化多孔材料来自天然的生物废料(包括木材、稻壳、玉米芯、棉花等)和人工处理过的生物质材料,如真空纤维棉等。源自生物质碳化衍生的多孔碳质材料价格便宜、无毒,其低密度、大比表面积和宽孔径分布给予多孔碳材料优异的吸收特性。这些特性使得多孔碳材料通过毛细管力、表面张力、氢键和范德华力等将相变材料约束在孔隙中,形成的复合相变材料既保持形状稳定,又因为碳骨架的存在而提高热能的传输速率,增强相变材料的热导率,解决了相变材料泄漏、热导率低的问题,提高相变材料储热性能。因此,生物质碳化衍生物的多孔碳材料不仅可以减少生物质直接燃烧所造成的环境污染,而且能够作为相变材料的支撑材料促进能源高效转化和利用,应用前景广阔,是热能储存利用的新兴材料。

本文综述了生物质碳化衍生物对相变材料形状稳定性和强化热导率的影响,重点关注生物质碳化衍生物及其改性方法对相变材料各向同性和各向异性热导率的强化。最后,总结生物质碳化衍生物多孔材料对相变材料热能储存特性特别是热导率方面的作用并展望生物质碳材料未来的研究前景。

2 生物质碳化衍生物多孔材料对相变材料各向同性和各向异性热导率的影响在相变材料热能储存利用领域中,热导率直接影响相变材料的储放热效率,根据碳化衍生物多孔材料碳骨架的无序均匀排列和定向有序排列的方式,可以将生物质直接碳化形成的多孔碳材料衍生物对相变材料热导率的强化分为各向同性热导率强化和各向异性热导率强化。相变材料自身较低的热导率会降低储放热速率,从而影响储能效率,生物质碳化衍生物多孔材料由于碳化纤维的存在形成导热骨架结构,对相变材料热导率起到强化作用,使相变材料能够对热能进行快速传递和存储。此外,为了满足特定的应用场合,比如为了提高太阳能的光热转化存储效率,一方面需要对太阳能转化形成的热能迅速地传递存储,另一方面又要减少存储的热能与外界环境的换热损失,从而需要构造出各向异性热导率结构,在高热导率方向进行热能传递存储,在低热导率方向减少换热损失,所以利用生物质纤维素的各向异性排列结构以碳化方式形成多孔碳材料,并和相变材料复合,强化相变材料的各向异性热导率。

2.1 各向同性热导率强化生物质碳化衍生物多孔材料对相变材料热导率的各向同性强化主要是通过维持生物质原有的细胞结构和纤维骨架结构,经过高温一次性碳化,利用碳结构的导热特性对相变材料的热导率进行强化。各向同性热导率的强化是由于生物质自身的骨架结构在轴向和径向均匀地生长,所以生物质碳化并和相变材料复合后,相变材料均匀地分散于生物质碳化多孔材料的孔中和表面,较高热导率的碳化纤维在相变材料的各个方向分布一致,对相变材料热导率的强化效果相同。

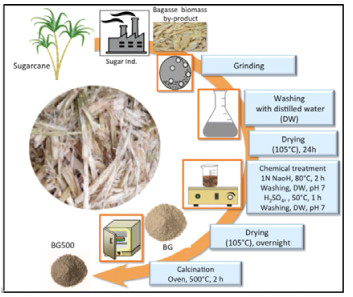

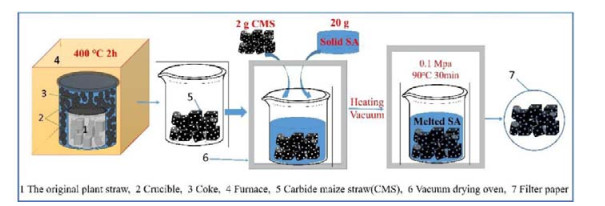

在生物质碳化形成的多孔材料中,一般使用的碳化原材料是一些废弃的农作物和木材等。通过碳化废弃的玉米芯[19]、不可食用的稻谷[20]、椰桃壳[21]、柚子皮[22]以及椰壳[23]、向日葵秸秆[24]、棉花[25]、木材等,形成多孔碳材料,并与有机相变材料复合,从而有效提高有机相变材料的热导率,且形成的复合相变材料形状稳定,不易液漏。Wen等[26]采用真空浸渍工艺制备硬脂酸/碳化玉米秸秆复合相变材料,如图 1所示,结果表明碳化玉米秸秆和硬脂酸具有良好的化学相容性,纯硬脂酸的热导率为0.18 W⋅(m·K)−1,而复合相变材料热导率为0.30 W⋅(m·K)−1,比纯硬脂酸高87.5%,适用于太阳能存储系统。Xie等[23]用过氧化氢对椰壳炭改性,增强对硬脂酸相变材料的负载,制备的形状稳定复合相变材料的热导率为0.75W⋅(m·K)−1,是纯硬脂酸(0.26 W⋅(m·K)−1)的2.88倍。Sheng等[25]通过碳化棉花真空浸渍石蜡形成形状稳定的复合相变材料,复合相变材料热导率由纯石蜡的0.250提高到0.434 W⋅(m·K)−1。陶璋等[27]{陶璋, 2020 #275}在1 000 ℃的管式炉中碳化松木和竹木并与石蜡复合形成复合相变材料,2种复合相变材料的相变潜热值均低于理论值,这可能是由于生物质多孔碳材料中含有少量的微孔结构,当相变材料在熔融过程中进入微孔后,相变的结晶过程受到空间限域作用的影响,造成结晶程度下降,进而使得相变过程中实际释放潜热值略低于理论潜热,松木多孔碳/石蜡、竹木多孔碳/石蜡复合相变材料热导率分别为0.48和0.76 W⋅(m·K)−1,比纯石蜡分别提高了100% 和216%。将成本极低的生物质废弃物和相变材料结合,一方面符合经济循环和资源再利用,另一方面又能提高有机相变材料的热导率,维持相变材料的形状稳定性,具有极高的成本效益。

|

图 1 硬脂酸/碳化玉米秸秆复合相变材料的制备原理[26] Fig.1 Preparation principle of stearic acid/carbonized corn straw composite phase change material [26] |

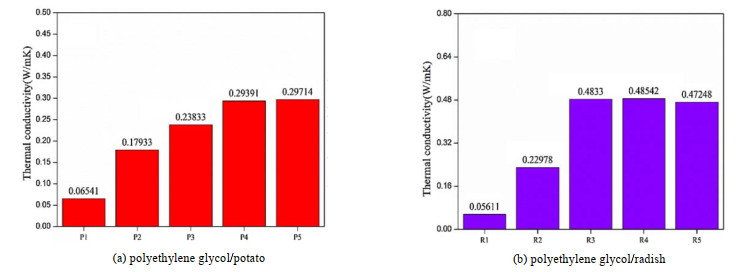

生物质以不同的碳化温度碳化或进行化学活化可以影响碳化结构的形状稳定性以及对相变材料的吸附能力,同时不同碳化温度或化学活化程度[28]会使生物质的石墨化程度不同,从而影响热导率的强化。如图 2所示,Zhao等[29]以400、800、1 100、1 300和1 600 ℃不同的温度碳化马铃薯和白萝卜多孔材料,蜂窝状多孔材料在1 300 ℃煅烧2 h具有最好蜂窝状结构,聚乙二醇/生物多孔碳复合相变材料热导率高达4.5 W⋅(m·K)−1,是聚乙二醇热导率的10倍左右。Atinafu等[30]使用Mg(OH)2模板法从棉纤维素碳化制备多孔碳,其比表面积达876.6 m2⋅g−1,将棉纤维素多孔碳材料用作十六醇的支撑材料,碳化温度分别为700、800和900 ℃的多孔碳支撑材料分别表现出高达85%、90% 和88% 的相变材料吸附能力,碳含量为15% 的复合相变材料热导率从十六醇的0.35提高到0.41 W⋅(m·K)−1,复合相变材料的导热性和热稳定性得到改善。Gökhan等[31]以核桃壳碳和活化的核桃壳碳为形状稳定和导热增强材料与棕榈酸甲酯相变材料复合,用于建筑物的热控制,棕榈酸甲酯/核桃壳碳和棕榈酸甲酯/活化的核桃壳碳复合相变材料热导率分别为0.72和0.60 W⋅(m·K)−1,是棕榈酸甲酯的1.9和1.6倍。生物质碳化多孔材料随着碳化温度的变化,其石墨化程度会有所改变,而以模板法或化学试剂活化也会影响碳结构的稳定性。因此,可以根据实际的需求改变碳化温度、使用模板法合成或活化碳材料,从而灵活改变生物质碳化多孔材料对相变材料的吸附量以及各向同性热导率的强化。

|

图 2 不同碳化温度下聚乙二醇/马铃薯和聚乙二醇/白萝卜复合相变材料的热导率[29] Fig.2 Thermal conductivity of polyethylene glycol/potato and polyethylene glycol/radish composite phase change materials at different carbonization temperatures[29] |

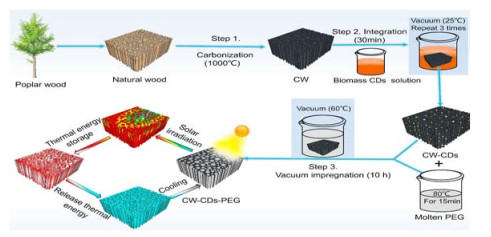

生物质碳化衍生物不仅可以维持相变材料形状稳定,提高有机相变材料的热导率,同时又具有优异的光热转换性能,这为相变材料对太阳能的热利用提供了良好的载体。Li等[32]将聚乙二醇掺入负载有碳点的多孔碳化木材中,复合相变材料形状稳定,热导率为0.449 W⋅(m·K)−1,比聚乙二醇高117%,具有84.4% 的优异光热转换效率(图 3)。Wang等[33]通过真空渗入法将十六胺和棕榈酸掺入向日葵花托和向日葵茎碳化气凝胶中,复合相变材料热导率分别为0.373和0.342 W⋅(m·K)−1,是纯十六胺和棕榈酸热导率的2.54和1.85倍,光热转换效率高达67.8%~75.6%。生物质碳化衍生物依靠碳结构对光的强吸收能力和自身的高导热能力使其在太阳能的热利用方面具有广阔的应用前景。

|

图 3 碳化木材-碳点-聚乙二醇复合相变材料的制备及光热转换和存储过程示意图[32] Fig.3 Schematic diagram of preparation, photo-thermal conversion and storage of carbonized wood-carbon point-polyethylene glycol composite phase change material[32] |

生物质碳化衍生物多孔材料对相变材料热导率的各向异性强化主要是利用生物原有的纤维素具有各向异性结构经过碳化保持定向有序排列碳纤维结构,使碳纤维在轴向和径向方向上的热导率存在显著的差异,复合后的相变材料也显示出各向异性的热导率。由于生物质的生长方式导致纤维素在输水方向(轴向)趋于定向排列,碳化纤维在轴向方向即面内方向相互连接形成导热通路,在垂直于面内方向即径向方向相互间隔形成较大界面热阻,最终导致生物质碳化多孔材料形成各向异性热导率结构,与相变材料复合后使各向同性热导率的相变材料强化成各向异性热导率的复合相变材料。

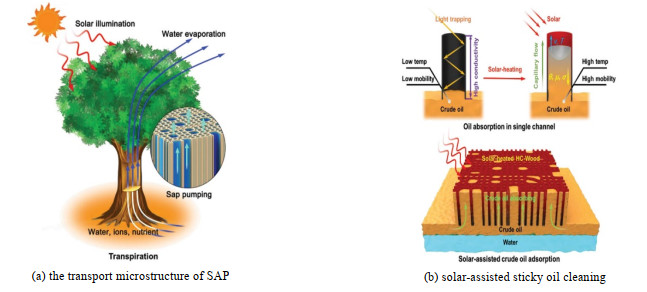

利用生物质原有的纤维素定向排列结构得到的碳化骨架可以强化各向异性的热导率,既在高热导率轴向上对太阳光快速吸收并传递热能,又在低热导率径向上减少热能损失,从而提高太阳能的热利用效率。最为常见的是利用天然木材[34-35]作为支架铺设导热通路,树木中垂直排列的微通道赋予木材各向异性和多孔结构,碳化后的木材显示出各向异性的热导率和良好的光吸收特性,其余的材料类似于玉米芯[36]、垂直排列的中空碳纤维棉毯[37]等。如图 4所示,Kuang等[38]在600 ℃碳化椴木,碳化后的椴木具有轴向方向0.6 W⋅(m·K)−1和径向方向0.3 W⋅(m·K)−1的各向异性热导率,300~2 500 nm光谱范围具有99.1% 的宽带太阳能吸收率。Li等[39]利用介孔椴木木材各向异性导热,即径向热导率和轴向热导率各为0.11和0.35 W⋅(m·K)−1,从而实现在太阳光下80% 高蒸气产生速率。因此,受生物质碳化多孔材料高蒸气产生速率启发,将碳化后具有各向异性热导率的生物质多孔材料与相变材料结合,通过碳化多孔材料结构特征赋予相变材料各向异性热导率的特性,同时提高相变材料的太阳能光热转化效率。

|

图 4 太阳光加热碳化木材吸收器用于黏性油清理[38] Fig.4 Solar heating carbonized wood absorbers for viscous oil cleaning[38] |

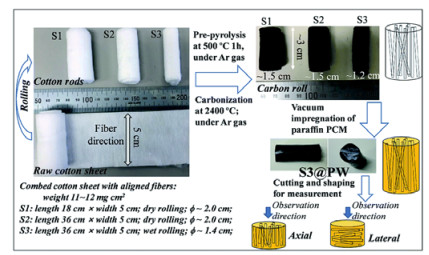

生物质碳纤维不同的碳含量会影响各向热导率的大小,而碳纤维的定向有序排列可以增强相变材料热导率的各向异性。Sheng等[40]在2 400 ℃氩气氛围中热解和碳化剑麻纤维,得到蜂窝碳骨架并复合石蜡相变材料,碳纤维的定向排列使得复合相变材料显示出各向异性的热导率,在碳纤维含量为12.8% 的复合相变材料径向和轴向热导率分别为0.62和1.73 W⋅(m·K)−1。如图 5所示,碳化纺织纯棉后[41-42],在碳质量分数为16.5% 时复合相变材料轴向热导率(0.99 W⋅(m·K)−1)是径向热导率(0.66 W⋅(m·K)−1)的1.5倍,远高于纯石蜡0.25 W⋅(m·K)−1的热导率;在碳质量分数为8.8% 时复合相变材料轴向热导率和径向热导率分别为0.77和0.58 W⋅(m·K)−1。所以,后续在调节生物质碳纤维衍生物复合相变材料各向热导率时可以参考改变碳纤维的含量对复合相变材料各向异性热导率进行调控。

|

图 5 碳纤维支架及相变材料/棉碳纤维复合材料生产原理图[41] Fig.5 Production principle of carbon fiber support and phase change material/cotton carbon fiber composite material[41] |

不同的碳化温度、模板法、溶剂协助碳化、添加功能化纳米粒子或采用不同性质的碳复合会影响生物质碳化衍生物碳骨架结构的稳定性[43],从而影响对相变材料的吸附量以及各向同性热导率的强化。

将生物质先以碱溶液[44-45]处理(见图 6),随后进行碳化是一种可以增大碳材料比表面积和孔隙率的方法,从而可以提高碳支撑材料对相变材料的吸收能力,也能进一步增强生物质碳基复合相变材料的各向同性热导率。Malik等[46]通过碱处理和热解将生物质原棉转化为中空碳纤维,碱处理的棉花热解后比表面积、孔体积和孔径分布都得到提高,增强的孔隙率提高对石蜡相变材料的封装能力,制备的碳支架提供导热纤维网络,随着石蜡相变材料质量的减少,复合相变材料的热导率从0.40增加到0.533 W⋅(m·K)−1,复合相变材料光热存储效率为76.4%。

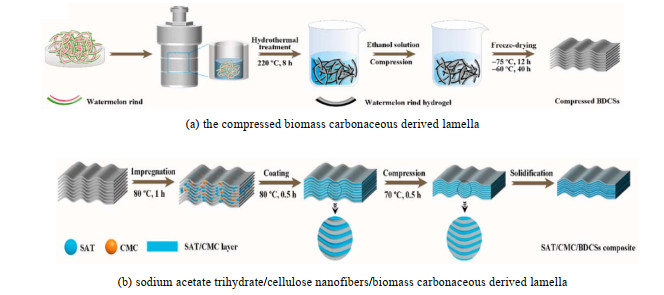

也有通过添加功能性纳米粒子Fe3O4[47]、以不同的碳化方法[48]以及活化[49]、形成气凝胶结构[50-51],或通过模板法强化生物质碳材料复合相变材料的各向同性热导率。Zhang等[52]将生物质瓜尔胶中的柔性碳源与聚酰亚胺中的硬脆碳源相结合,构建了一种新型均匀性增强的碳气凝胶,该气凝胶具有良好的多孔结构,刚性强,克服了传统碳气凝胶收缩严重、力学性能差的缺点,通过复合聚乙二醇相变材料形成的复合相变材料的导热系数可达0.62 W⋅(m·K)−1,有效提高了热响应速率,抗压强度达1.602 MPa,具有良好的光热转换性能,光热转化效率达到95%。Li等[53]通过木耳直接干燥、水热碳化以及水热和KOH辅助协同碳化3种方法探究其对硬脂酸相变材料吸附能力和强化热导率的影响,结果发现水热和KOH辅助协同碳化的方法具有最大的孔隙率和比表面积,有利于吸收大量相变材料,复合相变材料热导率为0.574 W⋅(m·K)−1,比纯硬脂酸增加115%。Ji等[54]为了提高相变材料导热性,以功能化聚苯乙烯纳米粒子为模板和可溶性淀粉为碳源,制备新型多孔碳,正十八烷/多孔碳复合相变材料热导率提高至0.631 W⋅(m·K)−1,相比正十八烷提高了266%。如图 7所示,Liu等[55]将西瓜皮通过水热法制成生物衍生碳质层并与三水醋酸钠相变材料复合,这种生物衍生碳质层具有特有的堆叠层状结构,所得复合相变材料表现出高导热性和优异的太阳能光热转换性能,复合相变材料热导率由纯三水醋酸钠的0.6提升到1.2 W⋅(m·K)−1,太阳能光热转换效率高达80.18%,比纯三水醋酸钠高53.7%。

|

图 7 压缩的生物质碳质衍生片层和三水醋酸钠/纤维素纳米纤维/生物质碳质衍生片层复合相变材料制备方法原理图[55] Fig.7 Schematic diagram of preparation of compressed biomass carbonaceous derivative lamella and sodium acetate trihydrate/cellulose nanofiber/biomass carbonaceous derivative lamella composite phase change materials[55] |

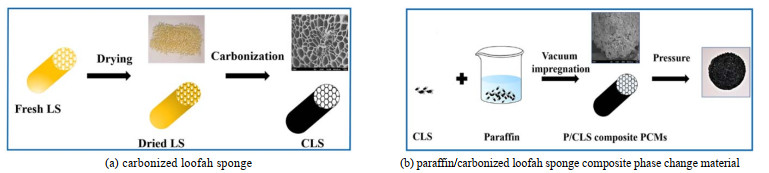

在提高生物质碳材料骨架结构稳定性和强化各向同性热导率的方法中,通过控制碳化温度[56-58]实现不同石墨化程度以维持碳材料结构稳定和增强热导率是最为常见的方法。Su等[59]以700、800、900 ℃的碳化温度碳化丝瓜棉得到蜂窝状多孔碳材料(图 8),研究发现随着碳化温度升高,复合相变材料的热导率也由0.267 9增加到0.296 9 W⋅(m·K)−1。Wu等[60]将人工培养的船型硅藻细胞分别在400和800 ℃下煅烧碳化,结果发现400 ℃下煅烧的硅藻壳比800 ℃下煅烧的硅藻壳具有较高的比表面积和良好的骨架,可以吸附质量分数为72.2% 的聚乙二醇相变材料,然而800 ℃下煅烧的硅藻壳热响应更快。

|

图 8 碳化丝瓜海绵和石蜡/碳化丝瓜海绵复合相变材料的制备示意图[59] Fig.8 Schematic diagram of preparation of carbonized loofah sponge and paraffin/carbonized loofah sponge composite phase change materials[59] |

将生物质碳化衍生物通过一些试剂预处理、改变原料的比例及环境条件、以不同的工艺制备或者引入导热添加剂可以对生物质碳化衍生碳材料各向异性的热导率产生影响。

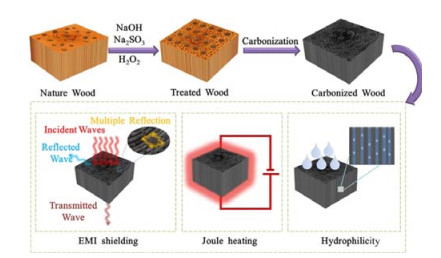

以碱溶液、催化剂及不同碳化温度等对生物质碳材料预处理会使生物质碳材料各向异性的热导率发生改变。Zhao等[61]发现源自原木的碳支架在径向和纵向的热导率分别为0.12和0.21 W⋅(m·K)−1,经过NaOH和Na2SO3的混合物及H2O2在60 ℃的脱木素处理后,化学碳化后的木材在径向和纵向的热导率变为0.14和0.58 W⋅(m·K)−1,木材各向异性的热导率增强,如图 9所示。Wang等[62]热解红橡木并用硫酸催化后在1 000 ℃管式炉中碳化,探究温度对各向异性热导率的影响,结果发现轴向热导率从室温到10.4 K会减少超过一个数量级,径向热导率从室温到77 K基本不改变。

|

图 9 多功能碳单体制备工艺示意图 [61] Fig.9 Schematic diagram of preparation of multi-functional carbon monomer[61] |

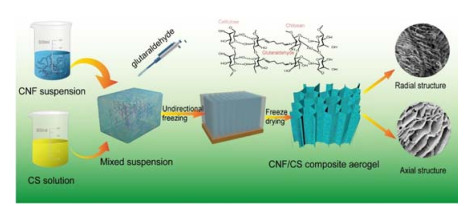

通过改变生物质原材料浓度[63]以及自身的密度、温度、形状尺寸[64-65]等或以不同制备工艺[66](传统熔融分散法和新型热压法)制备生物质碳材料也会对碳材料各向异性热导率产生影响。Zhang等[67]应用定向冷冻技术构建具有高度有序各向异性结构的纤维素纳米纤维/壳聚糖复合气凝胶(见图 10),结果发现复合气凝胶径向和轴向的热导率分别为0.028和0.036 W⋅(m·K)−1,随着壳聚糖质量分数从0变到1%,复合气凝胶2个方向的热导率先减小后略有增加,各向热导率可以随壳聚糖浓度的改变而改变。

|

图 10 纤维素纳米纤维/壳聚糖复合气凝胶的制备及结构组成示意图[67] Fig.10 Schematic diagram of preparation and structure of cellulose nanofiber/chitosan composite aerogel[67] |

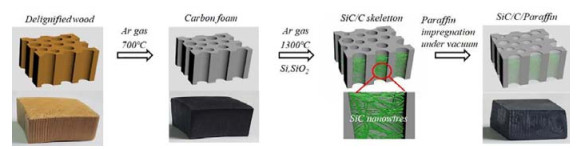

引入高导热的纳米粒子[68-69]或者碳纳米材料对生物质碳材料热导率的各向异性起到一定的调控作用。Wang等[70]将脱蜡松针在500 ℃下煅烧2 h得到松针衍生碳, 浸入硝酸银溶液中, 通过光沉积技术沉积银,以真空辅助渗透法制备银-松针衍生碳/环氧树脂复合材料,相比于松针衍生碳/环氧树脂复合材料面内0.206和穿透平面0.317 W⋅(m·K)−1的热导率,银-松针衍生碳/环氧树脂复合材料面内和穿透平面热导率分别提高到0.254和0.537 W⋅(m·K)−1,复合材料各向异性热导率得到增强。如图 11所示,Chen等[71]通过碳化松木并引入SiC纳米线强化石蜡相变材料的热导率,1 300 ℃下碳化松木/石蜡复合相变材料的横向和轴向热导率分别为0.35和0.57 W⋅(m·K)−1,而引入SiC纳米线后复合相变材料横向和轴向热导率分别为0.48和0.78 W⋅(m·K)−1,SiC纳米线的引入改变复合相变材料各向异性的热导率。Sun等[72]将碳纳米管与三维结构的轻木衍生碳支架相结合,并和天然橡胶复合,结果表明碳纳米管的结合使复合相变材料平面内和穿透平面的热导率从0.36和0.23 W⋅(m·K)−1增加到1.1和0.85 W⋅(m·K)−1,各向异性的热导率都得到了强化。

|

图 11 碳化硅/木质碳和相变复合物制备示意图[71] Fig.11 Schematic diagram of preparation of SiC/ woodiness carbon and phase change composite[71] |

生物质通过碳化可以形成各向同性和各向异性的热导率结构,不同的碳化温度影响生物质的石墨化程度,从而影响热导率的大小。利用生物质碳化衍生物形成的多孔碳材料可以对生物质资源进行循环再利用,极具经济效益,其多孔的结构解决了相变材料的液相泄漏问题,强化相变材料的热导率,给予相变材料各向异性热导率和增强太阳光吸收等特性,在太阳能热能储存利用等方面具有广泛的应用前景。

对于生物质碳化衍生物多孔碳材料未来的前景,主要有以下几点:

(1) 开发新型相变材料类型。目前生物质碳化衍生物多孔碳材料主要与有机相变材料复合,然而相比于有机相变材料,无机相变材料不易燃且价格便宜,储能密度更大,将生物质碳化衍生物多孔碳材料与无机相变材料结合也可用于热储能应用。

(2) 探究新型生物质碳化衍生物多孔碳材料复合材料。将生物质衍生碳材料和其他碳材料复合(比如石墨烯、碳纳米管、碳纤维等),进一步强化复合材料的热导率。

(3) 优化生物质碳化衍生物多孔碳材料改性方法。在生物质碳化衍生物多孔碳材料改性过程中需要使用一些危险和有害的试剂,这与环保和碳中和的理念相悖,因此需要改进生物质碳化衍生物多孔碳材料的活化过程,探究一种新型、高效、节能和环保的活化方法。

| [1] |

LI Y, SUN K, KOU Y, et al. One-step synthesis of graphene-based composite phase change materials with high solar-thermal conversion efficiency[J]. Chemical Engineering Journal, 2022, 429: 132439. DOI:10.1016/j.cej.2021.132439 |

| [2] |

FABIANI C, PISELLI C, PISELLO A L. Thermo-optic durability of cool roof membranes: Effect of shape stabilized phase change material inclusion on building energy efficiency[J]. Energy and Buildings, 2020, 207: 109592. DOI:10.1016/j.enbuild.2019.109592 |

| [3] |

LJUNGDAHL V, JRADI M, VEJE C. A decision support model for waste heat recovery systems design in data center and high-performance computing clusters utilizing liquid cooling and phase change materials[J]. Applied Thermal Engineering, 2022, 201: 117671. DOI:10.1016/j.applthermaleng.2021.117671 |

| [4] |

HIRMIZ R, TEAMAH H M, LIGHTSTONE M F, et al. Performance of heat pump integrated phase change material thermal storage for electric load shifting in building demand side management[J]. Energy and Buildings, 2019, 190: 103-118. DOI:10.1016/j.enbuild.2019.02.026 |

| [5] |

QIU L, YAN K, FENG Y, et al. Bionic hierarchical porous aluminum nitride ceramic composite phase change material with excellent heat transfer and storage performance[J]. Composites Communications, 2021, 27: 100892. DOI:10.1016/j.coco.2021.100892 |

| [6] |

WANG H, RAN X, ZHONG Y, et al. Ternary chloride salt-porous ceramic composite as a high-temperature phase change material[J]. Energy, 2022, 238: 121838. DOI:10.1016/j.energy.2021.121838 |

| [7] |

KONG X, JIANG L, YUAN Y, et al. Experimental study on the performance of an active novel vertical partition thermal storage wallboard based on composite phase change material with porous silica and microencapsulation[J]. Energy, 2022, 239: 122451. DOI:10.1016/j.energy.2021.122451 |

| [8] |

KHOR J O, YANG L, AKHMETOV B, et al. Application of granular materials for void space reduction within packed bed thermal energy storage system filled with macro-encapsulated phase change materials[J]. Energy Conversion and Management, 2020, 222: 113118. DOI:10.1016/j.enconman.2020.113118 |

| [9] |

PANDEY K, ALI S F, GUPTA S K, et al. Facile technique to encapsulate phase change material in an amphiphilic polymeric matrix for thermal energy storage[J]. Applied Energy, 2021, 292: 116917. DOI:10.1016/j.apenergy.2021.116917 |

| [10] |

FECZKÓ T, TRIF L, HORÁK D. Latent heat storage by silica-coated polymer beads containing organic phase change materials[J]. Solar Energy, 2016, 132: 405-414. DOI:10.1016/j.solener.2016.03.036 |

| [11] |

HAN D, GUENE LOUGOU B, Xu Y, et al. Thermal properties characterization of chloride salts/nanoparticles composite phase change material for high-temperature thermal energy storage[J]. Applied Energy, 2020, 264: 114674. DOI:10.1016/j.apenergy.2020.114674 |

| [12] |

áGUILA V B, VASCO D A, GALVEZ P P, et al. Effect of temperature and CuO-nanoparticle concentration on the thermal conductivity and viscosity of an organic phase-change material[J]. International Journal of Heat and Mass Transfer, 2018, 120: 1009-1019. DOI:10.1016/j.ijheatmasstransfer.2017.12.106 |

| [13] |

ZHANG X, ZHANG Y, YAN Y, et al. Synthesis and characterization of hydroxylated carbon nanotubes modified microencapsulated phase change materials with high latent heat and thermal conductivity for solar energy storage[J]. Solar Energy Materials and Solar Cells, 2022, 236: 111546. DOI:10.1016/j.solmat.2021.111546 |

| [14] |

LIU L, ZHENG K, YAN Y, et al. Graphene aerogels enhanced phase change materials prepared by one-pot method with high thermal conductivity and large latent energy storage[J]. Solar Energy Materials and Solar Cells, 2018, 185: 487-493. DOI:10.1016/j.solmat.2018.06.005 |

| [15] |

ZHU X, HAN L, YANG F, et al. Lightweight mesoporous carbon fibers with interconnected graphitic walls for supports of form-stable phase change materials with enhanced thermal conductivity[J]. Solar Energy Materials and Solar Cells, 2020, 208: 110361. DOI:10.1016/j.solmat.2019.110361 |

| [16] |

ZHAO B, WANG Y, WANG C, et al. Thermal conductivity enhancement and shape stabilization of phase change thermal storage material reinforced by combustion synthesized porous Al2O3[J]. Journal of Energy Storage, 2021, 42: 103028. DOI:10.1016/j.est.2021.103028 |

| [17] |

LEE W, KIM J. Cellulose nanofiber grafting and aluminum nitride deposition on the surface of expanded graphite to improve the thermal conductivity and mechanical properties of phase change material composites[J]. Composites Part B: Engineering, 2022, 230: 109526. DOI:10.1016/j.compositesb.2021.109526 |

| [18] |

张青峰, 朱钰漕, 张焕芝, 等. 生物质及其衍生材料在有机复合相变储能材料中的应用[J]. 现代化工, 2021, 41(7): 56-60, 67. ZHANG Q F, ZHU Y C, ZHANG H Z, et al. Application of biomass and its derived materials in organic composite phase change energy storage materials[J]. Modern Chemical Industry, 2021, 41(7): 56-60, 67. DOI:10.16606/j.cnki.issn0253-4320.2021.07.012 |

| [19] |

ZHANG W, ZHANG X, ZHANG X, et al. Lauric-stearic acid eutectic mixture/carbonized biomass waste corn cob composite phase change materials: Preparation and thermal characterization[J]. Thermochimica Acta, 2019, 674: 21-27. DOI:10.1016/j.tca.2019.01.022 |

| [20] |

ZHANG X, HUANG Z, YIN Z, et al. Form stable composite phase change materials from palmitic-lauric acid eutectic mixture and carbonized abandoned rice: Preparation, characterization, and thermal conductivity enhancement[J]. Energy and Buildings, 2017, 154: 46-54. DOI:10.1016/j.enbuild.2017.08.057 |

| [21] |

尚建丽, 陈丹, 武斌. 生物质多孔相变材料的制备及调温调湿性能研究[J]. 化工新型材料, 2015, 43(1): 107-109, 113. SHANG J L, CHEN D, WU B. Preparation of the biomass porous phase change materials and its thermal and moisture properties[J]. New Chemical Materials, 2015, 43(1): 107-109, 113. |

| [22] |

李绍伟, 傅彬彬, 李静. 碳化柚子皮基复合相变材料的制备及性能[J]. 复合材料学报, 2022, 39(6): 2885-2893. LI S W, FU B B, LI J. Preparation and properties of phase change composites based on carbonized pomelo peel[J]. Acta Materiae Compositae Sinica, 2022, 39(6): 2885-2893. DOI:10.13801/j.cnki.fhclxb.20210906.004 |

| [23] |

XIE B, LI C, ZHANG B, et al. Evaluation of stearic acid/coconut shell charcoal composite phase change thermal energy storage materials for tankless solar water heater[J]. Energy and Built Environment, 2020, 1(2): 187-198. DOI:10.1016/j.enbenv.2019.08.003 |

| [24] |

WEN R, ZHANG W, LV Z, et al. A novel composite phase change material of stearic acid/carbonized sunflower straw for thermal energy storage[J]. Materials Letters, 2018, 215: 42-45. DOI:10.1016/j.matlet.2017.12.008 |

| [25] |

SHENG N, NOMURA T, ZHU C, et al. Cotton-derived carbon sponge as support for form-stabilized composite phase change materials with enhanced thermal conductivity[J]. Solar Energy Materials and Solar Cells, 2019, 192: 8-15. DOI:10.1016/j.solmat.2018.12.018 |

| [26] |

WEN R, LIU Y, YANG C, et al. Enhanced thermal properties of stearic acid/carbonized maize straw composite phase change material for thermal energy storage in buildings[J]. Journal of Energy Storage, 2021, 36: 102420. DOI:10.1016/j.est.2021.102420 |

| [27] |

陶璋, 伍玲梅, 张亚飞, 等. 生物质多孔碳基复合相变材料制备及性能[J]. 工程科学学报, 2020, 42(1): 113-119. TAO Z, WU L M, ZHANG Y F, et al. Preparation and properties of biomass porous carbon composite phase change materials[J]. Chinese Journal of Engineering, 2020, 42(1): 113-119. |

| [28] |

HEKIMOğLU G, SARı A, KAR T, et al. Carbonized waste hazelnut wood-based shape-stable composite phase change materials for thermal management implementations[J]. International Journal of Energy Research, 2021, 45(7): 10271-10284. DOI:10.1002/er.6514 |

| [29] |

ZHAO Y, MIN X, HUANG Z, et al. Honeycomb-like structured biological porous carbon encapsulating PEG: A shape-stable phase change material with enhanced thermal conductivity for thermal energy storage[J]. Energy and Buildings, 2018, 158: 1049-1062. DOI:10.1016/j.enbuild.2017.10.078 |

| [30] |

ATINAFU D G, DONG W, WANG C, et al. Synthesis of porous carbon from cotton using an Mg(OH)2 template for form-stabilized phase change materials with high encapsulation capacity, transition enthalpy and reliability[J]. Journal of Materials Chemistry A, 2018, 6(19): 8969-8977. DOI:10.1039/C8TA01672K |

| [31] |

HEKIMOğLU G, SARı A, KAR T, et al. Walnut shell derived bio-carbon/methyl palmitate as novel composite phase change material with enhanced thermal energy storage properties[J]. Journal of Energy Storage, 2021, 35: 102288. DOI:10.1016/j.est.2021.102288 |

| [32] |

LI X, ZHU Z, YANG P, et al. Carbonized wood loaded with carbon dots for preparation long-term shape-stabilized composite phase change materials with superior thermal energy conversion capacity[J]. Renewable Energy, 2021, 174: 19-30. DOI:10.1016/j.renene.2021.04.078 |

| [33] |

WANG C, LIANG W, YANG Y, et al. Biomass carbon aerogels based shape-stable phase change composites with high light-to-thermal efficiency for energy storage[J]. Renewable Energy, 2020, 153: 182-192. DOI:10.1016/j.renene.2020.02.008 |

| [34] |

CHEN L, SONG N, SHI L, et al. Anisotropic thermally conductive composite with wood-derived carbon scaffolds[J]. Composites Part A: Applied Science and Manufacturing, 2018, 112: 18-24. DOI:10.1016/j.compositesa.2018.05.023 |

| [35] |

YANG H, WANG Y, YU Q, et al. Low-cost, three-dimension, high thermal conductivity, carbonized wood-based composite phase change materials for thermal energy storage[J]. Energy, 2018, 159: 929-936. DOI:10.1016/j.energy.2018.06.207 |

| [36] |

CHEN T, XIE H, QIAO X, et al. Highly anisotropic corncob as an efficient solar steam-generation device with heat localization and rapid water transportation[J]. ACS Applied Materials & Interfaces, 2020, 12(45): 50397-50405. |

| [37] |

SHENG N, ZHU R, NOMURA T, et al. Anisotropically enhanced heat transfer properties of phase change material reinforced by graphene-wrapped carbon fibers[J]. Solar Energy Materials and Solar Cells, 2020, 206: 110280. DOI:10.1016/j.solmat.2019.110280 |

| [38] |

KUANG Y, CHEN C, CHEN G, et al. Bioinspired solar-heated carbon absorbent for efficient cleanup of highly viscous crude oil[J]. Advanced Functional Materials, 2019, 29(16): 1900162. DOI:10.1002/adfm.201900162 |

| [39] |

LI T, LIU H, ZHAO X, et al. Scalable and highly efficient mesoporous wood-based solar steam generation device: localized heat, rapid water transport[J]. Advanced Functional Materials, 2018, 28(16): 1707134. DOI:10.1002/adfm.201707134 |

| [40] |

SHENG N, RAO Z, ZHU C, et al. Honeycomb carbon fibers strengthened composite phase change materials for superior thermal energy storage[J]. Applied Thermal Engineering, 2020, 164: 114493. DOI:10.1016/j.applthermaleng.2019.114493 |

| [41] |

SHENG N, ZHU R, DONG K, et al. Vertically aligned carbon fibers as supporting scaffolds for phase change composites with anisotropic thermal conductivity and good shape stability[J]. Journal of Materials Chemistry A, 2019, 7(9): 4934-4940. DOI:10.1039/C8TA11329G |

| [42] |

SHENG N, RAO Z, ZHU C, et al. Enhanced thermal performance of phase change material stabilized with textile-structured carbon scaffolds[J]. Solar Energy Materials and Solar Cells, 2020, 205: 110241. DOI:10.1016/j.solmat.2019.110241 |

| [43] |

王成君, 段志英, 苏琼, 等. 以多级孔碳为支撑基体的复合相变材料在光热转换与存储方面的研究进展[J]. 材料导报, 2020, 34(23): 23074-23080. WANG C J, DUAN Z Y, SU Q, et al. Research progress in photo-thermal conversion and storage of multistage porous carbon supported composite phase change materials[J]. Materials Reports, 2020, 34(23): 23074-23080. DOI:10.11896/cldb.19100096 |

| [44] |

AN J, LIANG W, MU P, et al. Novel sugar alcohol/carbonized kapok fiber composites as form-stable phase-change materials with exceptionally high latent heat for thermal energy storage[J]. ACS Omega, 2019, 4(3): 4848-4855. DOI:10.1021/acsomega.8b03373 |

| [45] |

TONY M A. From biomass residue to solar thermal energy: The potential of bagasse as a heat storage material[J]. Euro-Mediterranean Journal for Environmental Integration, 2020, 5(1): 17. DOI:10.1007/s41207-020-00158-y |

| [46] |

UMAIR M M, ZHANG Y, TEHRIM A, et al. Form-stable phase-change composites supported by a biomass-derived carbon scaffold with multiple energy conversion abilities[J]. Industrial & Engineering Chemistry Research, 2020, 59(4): 1393-1401. |

| [47] |

CHAO W, YANG H, CAO G, et al. Carbonized wood flour matrix with functional phase change material composite for magnetocaloric-assisted photothermal conversion and storage[J]. Energy, 2020, 202: 117636. DOI:10.1016/j.energy.2020.117636 |

| [48] |

LIU H, QIAN Z, WANG Q, et al. Development of renewable biomass-derived carbonaceous aerogel/mannitol phase-change composites for high thermal-energy-release efficiency and shape stabilization[J]. ACS Applied Energy Materials, 2021, 4(2): 1714-1730. DOI:10.1021/acsaem.0c02864 |

| [49] |

ATINAFU D G, JIN CHANG S, KIM K H, et al. Tuning surface functionality of standard biochars and the resulting uplift capacity of loading/energy storage for organic phase change materials[J]. Chemical Engineering Journal, 2020, 394: 125049. DOI:10.1016/j.cej.2020.125049 |

| [50] |

WEI Y, LI J, SUN F, et al. Leakage-proof phase change composites supported by biomass carbon aerogels from succulents[J]. Green Chemistry, 2018, 20(8): 1858-1865. DOI:10.1039/C7GC03595K |

| [51] |

NIU Z, YUAN W. Highly Efficient Thermo- and sunlight-driven energy storage for thermo-electric energy harvesting using sustainable nanocellulose-derived carbon aerogels embedded phase change materials[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(20): 17523-17534. |

| [52] |

ZHANG Q, XIA T, ZHANG Q, et al. Biomass homogeneity reinforced carbon aerogels derived functional phase‐change materials for solar-thermal energy conversion and storage[J]. Energy & Environmental Materials, 2021, 2: 12264. |

| [53] |

LI C, XIE B, HE Z, et al. 3D structure fungi-derived carbon stabilized stearic acid as a composite phase change material for thermal energy storage[J]. Renewable Energy, 2019, 140: 862-873. DOI:10.1016/j.renene.2019.03.121 |

| [54] |

JI R, WEI S, XIA Y, et al. Enhanced thermal performance of form-stable composite phase-change materials supported by novel porous carbon spheres for thermal energy storage[J]. Journal of Energy Storage, 2020, 27: 101134. DOI:10.1016/j.est.2019.101134 |

| [55] |

LIU H, ZHENG Z, QIAN Z, et al. Lamellar-structured phase change composites based on biomass-derived carbonaceous sheets and sodium acetate trihydrate for high-efficient solar photothermal energy harvest[J]. Solar Energy Materials and Solar Cells, 2021, 229: 111140. DOI:10.1016/j.solmat.2021.111140 |

| [56] |

LI Y, HUANG X, LI Y, et al. Shape-stabilized phase-change materials supported by eggplant-derived porous carbon for efficient solar-to-thermal energy conversion and storage[J]. Sustainable Energy & Fuels, 2020, 4(4): 1764-1772. |

| [57] |

SONG J, CAI Y, DU M, et al. 3D Lamellar structure of biomass-based porous carbon derived from towel gourd toward phase change composites with thermal management and protection[J]. ACS Applied Bio Materials, 2020, 3(12): 8923-8932. DOI:10.1021/acsabm.0c01196 |

| [58] |

LI S, LI J, GENG Y, et al. Shape-stable phase change composites based on carbonized waste pomelo peel for low-grade thermal energy storage[J]. Journal of Energy Storage, 2021, 103556. |

| [59] |

SU H, GUO X, CHEN G, et al. A novel honeycomb-like porous carbon from loofah sponge for form-stable phase change materials with high encapsulation capacity and reliability[J]. Materials Letters, 2022, 308: 131118. DOI:10.1016/j.matlet.2021.131118 |

| [60] |

WU B, LYU S, HAN H, et al. Biomass-based shape-stabilized phase change materials from artificially cultured ship-shaped diatom frustules with high enthalpy for thermal energy storage[J]. Composites Part B: Engineering, 2021, 205: 108500. DOI:10.1016/j.compositesb.2020.108500 |

| [61] |

ZHAO B, BAI P, WANG S, et al. High-performance joule heating and electromagnetic shielding properties of anisotropic carbon scaffolds[J]. ACS Applied Materials & Interfaces, 2021, 13(24): 29101-29112. |

| [62] |

WANG R, ZOBEIRI H, LIN H, et al. Anisotropic thermal conductivities and structure in lignin-based microscale carbon fibers[J]. Carbon, 2019, 147: 58-69. DOI:10.1016/j.carbon.2019.02.064 |

| [63] |

JIANG Z, OUYANG T, YANG Y, et al. Thermal conductivity enhancement of phase change materials with form-stable carbon bonded carbon fiber network[J]. Materials & Design, 2018, 143: 177-184. |

| [64] |

YU Z T, XU X, FAN L W, et al. Experimental measurements of thermal conductivity of wood species in China: Effects of density, temperature, and moisture content[J]. Forest Products Journal, 2011, 61(2): 130-135. DOI:10.13073/0015-7473-61.2.130 |

| [65] |

KUMAR R R, KOLAR A K, LECKNER B. Shrinkage characteristics of Casuarina wood during devolatilization in a fluidized bed combustor[J]. Biomass and Bioenergy, 2006, 30(2): 153-165. DOI:10.1016/j.biombioe.2005.11.005 |

| [66] |

NOMURA T, TABUCHI K, ZHU C, et al. High thermal conductivity phase change composite with percolating carbon fiber network[J]. Applied Energy, 2015, 154: 678-685. DOI:10.1016/j.apenergy.2015.05.042 |

| [67] |

ZHANG M, JIANG S, HAN F, et al. Anisotropic cellulose nanofiber/chitosan aerogel with thermal management and oil absorption properties[J]. Carbohydrate Polymers, 2021, 264: 118033. DOI:10.1016/j.carbpol.2021.118033 |

| [68] |

YUAN Y, SUN X, YANG M, et al. Stiff, thermally stable and highly anisotropic wood-derived carbon composite monoliths for electromagnetic interference shielding[J]. ACS Applied Materials & Interfaces, 2017, 9(25): 21371-21381. |

| [69] |

WANG Y, TANG B, GAO Y, et al. Epoxy composites with high thermal conductivity by constructing three-dimensional carbon fiber/carbon/nickel networks using an electroplating method[J]. ACS Omega, 2021, 6(29): 19238-19251. DOI:10.1021/acsomega.1c02694 |

| [70] |

WANG Y, JI C, YAN C, et al. Improved Thermal conductive property of pine needle derived carbon for thermal management applications: 2018 20th International Conference on Electronic Materials and Packaging [C]. Hong Kong: Institute of Electrical and Electronics Engineers, 2018.

|

| [71] |

CHEN Z, ZHU R, SHENG N, et al. Synchronously improved thermal conductivity and anti-leakage performance for phase change composite by SiC nanowires modified wood carbon[J]. Journal of Energy Storage, 2022, 47: 103567. DOI:10.1016/j.est.2021.103567 |

| [72] |

SUN H, JI T, BI H, et al. Synergistic effect of carbon nanotubes and wood-derived carbon scaffold on natural rubber-based high-performance thermally conductive composites[J]. Composites Science and Technology, 2021, 213: 108963. DOI:10.1016/j.compscitech.2021.108963 |