农业废弃物资源化利用是生态文明建设的重要内容,也是农业农村绿色低碳发展的内在要求[1]。好氧堆肥作为一种有机废弃物减量化、无害化、资源化的有效途径,在各种农业废弃物的处理利用中广泛应用。然而,由于堆肥过程高温、碱性环境以及厌氧、好氧区域共存等特性,在降解有机物的同时也会产生氨气(NH3)等臭气和甲烷(CH4)、氧化亚氮(N2O)等温室气体,造成环境污染和营养成分损失[2]。为减少堆肥过程中相关气体排放,调整碳氮比(C/N)、pH值和通风速率等堆肥工艺参数是前期研究的重点,但气体减排效果有限[3]。研究表明,添加剂可使堆肥总氮、总碳损失分别减少30.2% 和25.5%,是减少农业废弃物堆肥过程中NH3和温室气体排放的有效方法[2],但农业废弃物与添加剂配伍组合复杂,堆肥原料的性质、添加剂种类及用量的不确定性会相互作用,直接影响气体减排效果的稳定性。Liu等[4]将纳米零价铁、过硫酸钾、玉米秸秆生物炭和猪粪生物炭添加到以猪粪、玉米秸秆和蔬菜为原料的堆肥中以探究其对堆肥过程中气体排放的影响,发现猪粪生物炭对N2O减排效果最好,为13.3%,过硫酸钾通过降低pH使NH3排放减少53.1%。Luo等[5]研究发现,0.2% 双氰胺和5% 磷石膏联用会增加猪粪和玉米秸秆混合堆肥过程中NH3排放量;当磷石膏添加量增加至10% 时,通过影响硝化反应,分别使NH3减排22.8% 和N2O减排33%。因此,使用添加剂是减少堆肥过程中气体排放的有效措施,也是控制碳氮流失、提高堆肥品质的重要手段,探明添加剂对堆肥碳氮循环过程、堆体理化性质及微生物特性的影响是研究热点。

本研究梳理了近年来国内外农业废弃物堆肥过程气体排放及减排的相关文献,分析了生物添加剂、有机添加剂和无机添加剂的特点,以及在农业废弃物好氧堆肥中应用的研究进展,比较了不同添加剂促进NH3和温室气体减排的机理,以期为农业废弃物好氧堆肥NH3和温室气体的协同减排、提高堆肥效率和产品质量提供重要的理论依据与参考。

2 好氧堆肥添加剂种类及作用 2.1 有机添加剂有机添加剂对促进有机物矿化、调节温室气体排放、钝化重金属和改善堆肥性能均有积极作用,主要包括生物炭、生物表面活性剂、三羧酸循环调节剂、腐殖质前体等,特点和功能如表 1所示[6-13]。有机添加剂对堆肥的影响主要有2个方面:(1)平衡堆肥C/N并提供大量可供分解的有机物,增强堆肥产品在施用后的有效性[14];(2)为微生物生长繁殖提供养分和适宜的环境,提高微生物群落丰度,促进有机物到腐殖质的转化过程[15]。

|

|

表 1 堆肥添加剂功能及适用性分析 Table 1 Function and applicability analysis of compost additives |

生物炭具有比表面积大、持水能力强等特点,可以改善堆体环境,提高木质纤维素降解真菌丰度,促进堆肥腐殖化[16];高孔隙率和吸附能力可以为微生物提供附着位点[17],并通过影响功能性微生物群落结构,改变相关功能基因和酶的有效性[18]。Liu等[19]在树枝、牛粪混合堆肥中发现,添加10% 的秸秆生物炭可增加硝化细菌相关丰度,使有机质降解率提高25%。以鼠李糖脂为代表的生物表面活性剂具有两亲性结构,可以降低纤维素上水膜的表面张力,加速疏水性化合物水解,促进堆肥腐殖化,进而缩短堆肥时间2~3 d[7]。三磷酸腺苷(ATP)和烟酰胺腺嘌呤二核苷酸(NADH)是三羧酸循环的主要调节因子,可以对循环产生反馈抑制作用并增强碳保存[8],提高堆肥品质。Yu等[20]研究发现,ATP和NADH分别通过糖胺缩合途径、木质素-蛋白途径和纤维素高效降解促进腐殖质形成,在秸秆堆肥中分别减少CO2排放32.2%、26.7%。氨基酸、多糖等腐殖质前体可以有效促进堆肥腐熟[8]。Zhang等[9]研究表明,氨基酸可以通过美拉德反应参与腐植酸的形成,与对照组相比,提高堆肥产品中腐植酸含量约1倍。亮氨酸和苯丙氨酸可以提高秸秆堆肥中细菌群落的稳定性与复杂性,提高固氮微生物活性,同时减弱反硝化作用,促进氮保留[21]。葡萄糖作为微生物的碳源和能源,可以促进胡敏酸向腐植酸转化[22]。

2.2 无机添加剂无机添加剂主要包括黏土矿物、无机盐类和金属单质及氧化物,具有成本低、环保、比表面积大的特点,通过增加堆体孔隙率、改善堆肥环境、稳定pH值优化堆体的物理性能[23],常用于促进堆肥过程中有机物的降解和腐殖化。三类无机添加剂的特点如表 1所示,黏土矿物作用机制与生物炭相似[10],但由于价格低廉,在生产中的应用更为广泛;无机盐类添加剂通过影响堆肥环境(特别是酸碱度)调节堆肥进程,适用于pH变化幅度大的单一物料发酵[11-12];金属类添加剂利用其自身的导电性和强氧化性促进物料分解,强化堆体内电子传递,加快氧化还原反应[13]。

膨润土[10]、沸石[24]和海泡石[25]是以硅酸盐为主要成分的黏土矿物,由于阳离子交换能力高、孔隙率高、表面积大、微生物粘附能力出色等特点,在好氧堆肥中应用广泛。其中,膨润土可使溶解性有机碳和有机质降解速率提高21.33%~28.19%,并通过吸附和络合降低锌、铜可利用度,使堆肥产品具有更高的成熟度和更低的毒性[10]。沸石和海泡石具有与膨润土相似的吸附能力和离子交换性能,Zheng等[25]发现海泡石可分别降低Cu和Zn生物利用度11.0%~15.9% 和15.4%~26.5%,对重金属钝化起到关键作用。总的来说,黏土矿物作用于堆肥的直接机制是其中的Al3+和Mg2+对Si4+同晶替换产生的离子交换吸附特性[26],间接机制则是多孔径和大比表面积可为微生物繁殖创造有利的环境。

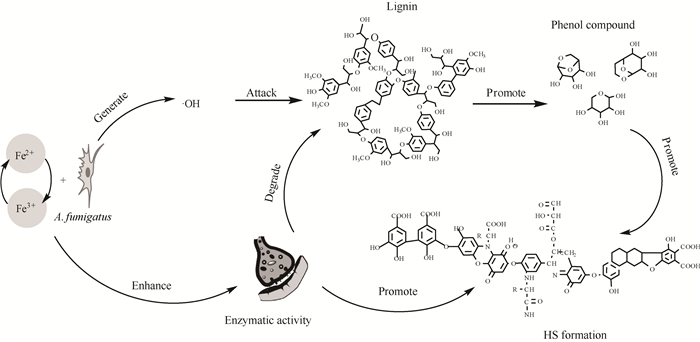

无机盐类添加剂通过改变堆体pH和影响相关元素改善堆肥。过磷酸钙或磷石膏可以促进高芳香性腐植酸的聚合,从而提高堆肥的腐熟度。过量磷盐会降低堆体pH值进而抑制微生物活性和有机物的生物降解,但对于含氮高的畜禽粪便,低pH可抑制氨的释放,提高堆肥氮保存[27-28]。石灰和磷酸钙镁作为碱性添加剂可以通过抑制产甲烷菌、芽孢杆菌和调节基质pH提高堆肥成熟度,并可使堆肥过程中CH4、N2O和NH3减排22%~81% [29]。零价铁具有大表面积、强还原性等特点,可用作导电材料,在蔬菜废弃物堆肥中促进微生物迁移,延长高温期不仅使堆肥有机质损失减少11.8%,还能显著降低产品的生物毒性[30-31]。金属氧化物主要通过在堆肥体系中构建类芬顿体系,促进木质纤维素降解[32],在提高农作物秸秆、果树剪枝等物料的堆肥效率方面具有突出作用。烟曲霉和FeO可在秸秆堆肥过程中建立类芬顿反应,提高木质纤维素的降解效率,使腐殖质和腐植酸浓度分别提高96.4% 和255.8% [33],反应机理如图 1所示。

|

图 1 类芬顿反应促进纤维素解聚机理 Fig.1 Mechanism of Fenton-like reaction promoted cellulose depolymerization |

生物添加剂可以分为单一菌株和复合菌剂。堆肥中微生物群落的演替反映了其对堆肥原料的降解能力,外源微生物促进堆肥腐熟的作用机制主要是分泌基于底物的水解酶和优化种群结构[30],如放线菌可以使堆肥过程中木质纤维素降解率提高34.3%,酶活性提高8.3% [34]。此外,特定微生物种群可以通过代谢转化和生物降解来保留更多的氮、磷养分。如表 1所示,农业废弃物堆肥中广泛使用的菌株主要有纤维素降解类、保氮类和嗜热类微生物,其中接种保氮微生物有利于构建多样化的重氮营养菌群落,减少氮损失9.3% [35];溶磷菌通过酶的水解促进不溶性磷的转化和有机磷化合物的矿化,可使堆肥中有效磷、总磷和腐殖质含量分别提高6.8%、11.1% 和9.1% [36];嗜热菌可加速有机质降解,释放大量能量,促进堆肥温度快速升高,抑制硝化细菌活性,使N2O排放降低50.8% [37]。与细菌和放线菌相比,真菌可以在堆肥的不同阶段加速木质纤维素降解,比如嗜热真菌可以在堆肥高温期存活,青霉菌、木霉菌和地曲霉等可以在降温期生长和繁殖[38]。

由于不同菌株对环境的适应性差异较大,单一菌株稳定性容易受到底物条件的影响,且堆体中天然微生物的竞争也会降低功能性单一菌株的有效性。不少学者研究了复合菌株对堆肥过程的影响,并取得较好效果。复合菌剂可增强细菌和真菌群落的相互作用,促进木质纤维素降解和碳水化合物代谢,产生更多腐殖质前体,Wu等[39]在秸秆堆肥过程中添加由豚鼠气单胞菌、根瘤菌、假结核棒杆菌和棒状链霉菌组成的木质纤维素降解菌剂,与对照组相比,有机物和粗纤维降解速率分别提高了7.58%、8.82%。李文玉等[40]以农业废弃物为原料,添加白腐菌和放线菌构成的复合菌剂,能够加速堆体升温,使堆肥腐熟时间缩短5~15 d。成熟堆肥作为稳定的发酵产物,可以促进微生物三羧酸循环,增强碳水化合物和氨基酸代谢,加速堆体温度升高,从而使病毒和病原体失活[41]。由木霉属、帚霉属组成的复合菌剂可以丰富真菌群落多样性,提高木质素降解真菌属的相对丰度,使玉米秸秆堆肥腐殖化度提高90% [42]。某公司将芽孢杆菌、地芽孢杆菌、超嗜热菌、甲基营养型芽孢杆菌复配制成超高温菌剂,可大幅提高堆肥温度20~30 ℃,缩短堆肥腐熟时间30% [43]。

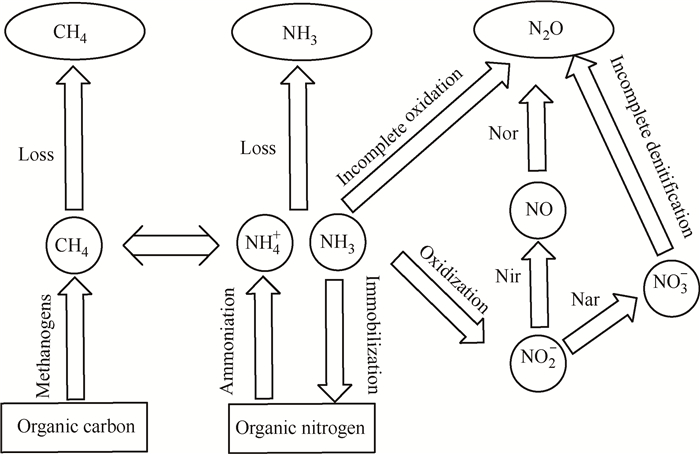

3 添加剂对堆肥过程气体排放的影响 3.1 堆肥过程气体排放原理堆肥过程的气体排放是一个复杂的反应过程(图 2)。有机物降解后,有机氮和有机碳在堆肥中以蛋白质、肽、核酸、氨基酸、多糖等形式存在[44]。含氮物质通过氨化作用氧化脱氨产生NH4+和NH3,NH4+和NH3通过水相中的NH3·H2O保持平衡[45],在堆肥初期高pH值和高温环境下,平衡向产生NH3的方向移动,导致NH3排放增多。硝化作用和反硝化作用是堆肥氮转化的关键过程。硝化作用首先通过各种氨氧化细菌将NH3/NH4+还原成NO2-[46],再在硝化杆菌等的帮助下将NO2-氧化为NO3-[47];反硝化作用是细菌在缺氧条件下依次将NO3-还原为NO2-、NO、N2O、N2的过程,分别由硝酸盐还原酶(Nar)、亚硝酸盐还原酶(Nir)、一氧化氮还原酶(Nor)和氧化亚氮还原酶(Nos)催化[48]。N2O通过有氧条件下的生物硝化作用和缺氧条件下的不完全反硝化作用或氨不完全氧化产生[47]。CH4排放是产甲烷菌与甲烷氧化菌平衡后的结果[49],其中产甲烷菌在厌氧环境中将有机碳转化为CH4,甲烷氧化菌可将CH4进一步氧化为CO2[50]。堆肥过程中气体排放相互关联,与碳氮循环过程紧密相关。有机物在微生物作用下完全氧化分解为微生物提供能量来源,同时也影响堆体温度和特征微生物群落,进而影响NH4+的转化[50]。堆体中含氮物质被好氧微生物降解为溶解氮,NH4+浓度对产甲烷菌和甲烷氧化菌存在影响,在一定程度上影响CH4的排放[48]。

|

图 2 堆肥过程中主要气体排放途径 Fig.2 Main pathways of gas emission in aerobic composting |

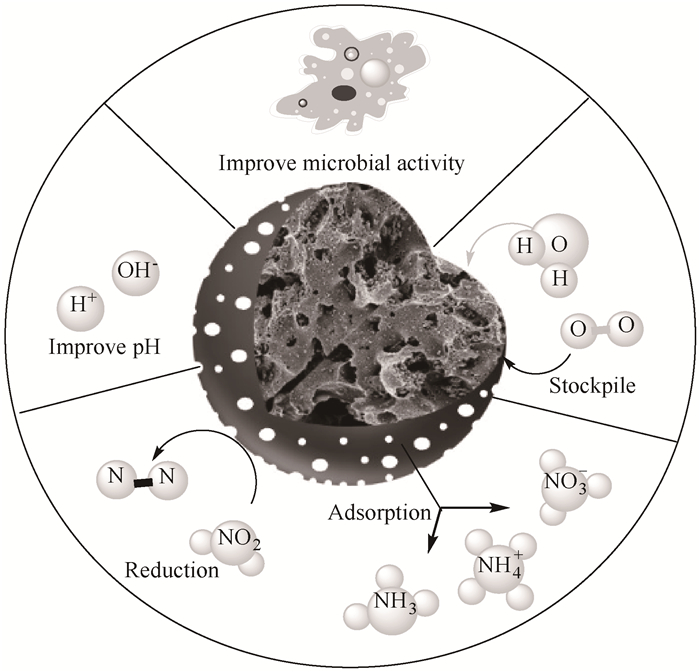

生物炭是减少堆肥气体排放的高效有机添加剂,具有高度稳定的特性。生物炭降低NH3排放的机制主要有两方面:(1)发达的孔隙结构、大比表面积和官能团对NH3/NH4+具有强吸附性,可以直接降低NH3排放[51];(2)多孔生物炭可以调节堆肥堆体温度、水分、孔隙度等因子[18],增加堆肥中硝化细菌和纤维素酶活性,可以强化NH4+/NH3的固定并加速将其还原为硝酸盐,同时还可使纤维素分解产生更多的可溶性有机碳,从而提高微生物对NH4+的利用率,降低NH3排放[52-53]。生物炭对CH4排放的影响主要通过产甲烷菌和甲烷氧化菌实现,通过改善堆体通风和供氧抑制厌氧区的形成,增强甲烷氧化菌的活性;通过吸附作用减弱NH4+对甲烷单加氧酶的活性抑制,提高甲烷氧化菌的氧化能力,同时降低产甲烷菌的氮可用性,从而抑制其生长[53]。N2O的排放受到硝化反应和反硝化反应的耦合控制,生物炭可以直接吸附N2O并将其还原为N2[54],也可吸附堆肥过程中的NH4+和NO3-,减少硝化和反硝化细菌可用的无机氮,从而减少N2O排放[13]。此外,生物炭可改善堆体氧气流通,抑制厌氧条件下的反硝化酶活性,即抑制Nir基因表达、增强Nos基因表达[55],从而减少N2O排放。

如表 2所示[6, 24, 56-59],生物炭可以减少13%~71% 的N2O和24%~70% 的CH4排放,对NH3减排效果不佳的原因可能是生物炭会略微增加堆体的初始pH值,增强NH4+向NH3的转化。也有研究指出,5% 小麦秸秆生物炭可加速有机物分解,使牛粪、蔬菜混合堆肥的CH4累积排放量提高15.5% [60]。生物炭的减排效果主要取决于堆肥原料类型、堆肥工艺、生物炭类型及比例,通常认为质量分数为4%~20% 的生物炭有利于氮保存,过量添加会提高堆体的pH值,促进NH4+向NH3转化[61],降低保氮效果,并增加堆肥成本。Sánchez-garcía等[62]研究表明,3% 添加量可以缩短堆肥时间,但对CH4、N2O排放均无显著影响;添加量为5%~20% 时,温室气体减排效果与添加量呈正相关。生物炭对堆肥减排作用机制如图 3所示,生物炭既可以通过中和、吸附等方式收集堆肥排出的碳氮气体,实现回收再利用的目的,也可以优化堆肥过程参数、改善微环境减少气体排放。因此,探索更广泛的生物炭原料来源,深入了解生物炭对堆肥的作用机制和效果是未来研究重点。

|

|

表 2 有机添加剂对农业废弃物堆肥的气体减排效果 Table 2 Effect of gas emission reduction with organic additives in agricultural waste composting |

|

图 3 生物炭减排机理 Fig.3 Mechanism of gas emission reduction by biochar |

葡萄糖、淀粉等有机添加剂易被微生物降解利用,并促进NH4+到有机氮的转化,分别减少NH3挥发26.9%、11.8% [63]。Guo等[64]通过微生物模块化分析,发现麦芽糖和蔗糖改变了堆肥核心微生物群落的组成和结构,促进了铵的同化,并且双糖的添加也使核心微生物群落对有机氮生成的参与度从29.0% 提升到85.3%。但受限于价格,多糖的使用仅停留在实验室阶段。木醋液是一种以醋酸为主要成分的天然植物素材,由70%~85% 的水和酸类、酚类、醇类构成,pH值在2.0~3.5,通过提供酸性底物使N2O和CH4排放分别降低69% 和68% [24],但由于低pH和高水分含量,在畜禽粪便和蔬菜废弃物堆肥中的应用受限。

3.3 无机添加剂对堆肥气体排放的影响无机添加剂中如沸石[24]、药石[24]、膨润土[65]、黏土[66]等矿物添加剂可提高堆体孔隙率,提高氧气传输效率,并刺激微生物的新陈代谢活动,可使温室气体排放降低59.3%~80.8%,如表 3所示[5, 24, 29, 67-70]。黏土矿物与生物炭在堆肥中作用相似,但生物炭可在堆体内搭建电桥,促进NO3-和NH4+转化,而黏土矿物是通过大孔隙结构促进堆体通风,去除原料中多余水分,为好氧微生物生长提供空间,具体表现为促进甲烷氧化菌和N2O消耗细菌生长,抑制甲烷生成菌和N2O生成菌生长[71]。Mao等[24]在猪粪堆肥中分别加入5% 的沸石和药石,发现添加剂在改善堆体环境的同时提高了堆肥成熟期的细菌多样性,但由于沸石具有更高的还原效率,显著降低了N2O排放,而药石通过抑制微生物活性,从而降低含氮化合物的分解,表现出更好的CH4和NH3减排效果。宋修超等[72]在工厂条垛式猪粪好氧堆肥中加入沸石,可使NH3排放减少8.2%。石灰可减少氨氧化细菌基因丰度,增加氧化亚氮还原细菌基因丰度,N2O排放减少47.8% [47]。Wu等[65]发现膨润土可以使CH4和N2O排放减少17% 和29%,温室气体排放总量减少25.1%。Ren等[66]研究表明,添加黏土使猪粪堆肥中CH4和N2O的排放量分别减少45.9% 和86.8%。无机盐类在减少NH3排放方面更有效,减排效果在21.7%~59.2%。镁盐和钙盐通过PO43-与堆肥中的NH4+结合形成鸟粪石和其他稳定化合物,抑制NH4+转化为NH3,实现NH3稳定减排。Jiang等[68]将过磷酸钙和硫酸镁引入猪粪堆肥中,使得NH3和CH4排放量显著降低59.2% 和64.9%,同时促进堆肥成熟。此外,亚铁盐[69]、过磷酸钙[68]和磷石膏[5]等酸性添加剂通过直接或离子水解间接降低pH值,导致NH3和NH4+之间的平衡向NH4+方向倾斜,降低了NH3排放。同时,低pH可抑制产甲烷菌生长,使CH4排放减少45.5%~89.7%。但与有机酸不同的是,酸性添加剂降低堆体pH,会导致N2O排放量增加[73]。原因在于有机酸中含有易于分解的碳源,其生物降解会消耗堆体内氧气,抑制氨氧化细菌生长并降低N2O排放[74]。

|

|

表 3 无机添加剂对农业废弃物堆肥的气体减排效果 Table 3 Effect of gas emission reduction with inorganic additives in agricultural waste composting |

生物添加剂可通过改变微生物群落组成和相关酶代谢活性来减少堆肥气体排放,减排效果如表 4[75-78]所示。嗜热芽孢杆菌可增加鸡粪堆体内乳酸芽孢杆菌和硝化细菌的相对含量,从而降低pH值和促进NH4+-N向NO3--N转化,使NH3排放降低27.8% [79]。接种放线菌等嗜热菌,可通过提高堆肥初期温度和NH4+-N水平抑制硝化细菌活性,减少N2O排放50.8%,但有机质的快速分解可为产甲烷菌提供大量底物,使CH4排放量大幅增加[36]。Jiang等[78]在堆肥中分别添加肠杆菌素和腐霉菌素,结果发现,肠杆菌素可促进碳水化合物降解和氨基酸代谢相关菌群生长,CH4排放减少18.3%;腐霉菌素可提高微生物多样性,促进菌群相互作用,使反硝化过程衰减,N2O排放减少27.47%。氨氧化古菌可通过硝化作用加速铵态氮转化为亚硝酸盐和硝酸盐,从而减少NH3排放高达82.1% [80]。单一菌种难以兼顾多种气体减排,实际生产中多采用复合微生物菌剂来提高对堆肥的促进效果。Yu等[81]将木质纤维素降解微生物接种至猪粪堆肥中以降低反硝化基因的丰度,使NH3排放减少25.9%。Tian等[76]发现由地衣芽孢杆菌、枯草芽孢杆菌和金青霉组成的复合菌剂会提高放线菌和变形菌相对丰度,加速有机物分解,促进氮素转化,在提高堆肥产品质量的同时分别减少NH3和N2O排放65.7% 和18.9%。木质纤维素降解微生物接种会改变堆肥环境,抑制反硝化细菌群落的演化,降低参与反硝化过程的Nir和Nos基因的丰度,使N2O排放减少34.98% [81]。李舒清等[77]通过在牛粪堆肥中接种淀粉芽孢杆菌和灰绿曲霉,降低堆体中产甲烷菌丰度,增加甲烷氧化菌丰度,显著降低CH4排放27.5%。

|

|

表 4 生物添加剂对农业废弃物堆肥中气体减排效果 Table 4 Effect of gas emission reduction with biological additives in agricultural waste composting |

相比于单一添加剂,复合添加剂可综合多种添加剂的优点,实现功能互补,产生协同效应,有效减少堆肥过程中的气体排放;同时还能减少单一添加剂的用量,降低成本,并提高堆肥的稳定性。其中,有机和无机添加剂组合对减少温室气体排放更为有效,例如生物炭和沸石可以通过降低Nir基因丰度来抑制反硝化过程,增加Nos功能基因丰度,使N2O排放量降低38.9% [71]。无机添加剂中,加入磷石膏,可降低堆体pH,弥补了双氰胺显著增加NH3排放的缺点[82],使NH3、CH4和N2O排放分别降低18.3%、38.6% 和36.1% [83]。有机添加剂和生物添加剂复合后,生物炭可为微生物提供合适的生长环境,提高微生物代谢活性,与单独添加生物炭相比,NH3、CH4和N2O排放分别降低27.4%、38.2% 和54.1% [84]。单独添加木醋液或生物炭会减少NH3挥发22%~23%,但二者联合使用可有效减少低pH对堆体的影响,提升添加剂的有效性,使NH3排放减少59% [85]。

4 结语添加剂可有效减少农业废弃物堆肥过程中的NH3和温室气体排放,对于促进堆肥进程、改善堆肥产品质量和保护生态环境具有重要意义。以生物炭为代表性的有机添加剂既可通过增加微生物和酶活性促进堆肥腐殖化,提高碳氮保存率,减少气体排放;也可利用优良的物理性质吸附气体,有效减少气体散逸。大多数无机添加剂具有比表面积大、吸附能力强、离子交换能力强等特点,在减少NH3排放和抑制CH4产生方面效果显著。值得注意的是,有机和无机添加剂虽然减排效果较好,但存在成本高、盐离子含量高、不可重复利用等问题,且长期使用可能会对土壤产生不利影响。此外,由于微生物活性受原料特性和堆肥环境参数等影响,生物添加剂的气体减排效果难以保证。基于不同添加剂的特点,未来控制堆肥过程NH3和温室气体排放的研究应重点关注以下几个方面:

(1) 堆肥过程的气体减排效果会随着添加剂类型、废弃物性质和施用剂量而变化,研究中采用的调控措施往往会对多个因素产生影响,从而引发多重效应甚至掩盖真实现象。为追求更低的排放效果和更高的堆肥质量,未来需进一步研究有机、无机和生物添加剂的科学组合,以期发挥不同添加剂的优势,达到“1+1>2”的效果。

(2) 堆肥过程中NH3和温室气体的产生与排放相互关联,但碳氮转化的微生物作用机制和成分转化过程目前尚不清楚,可探索借助同位素等现代科学技术,明确碳氮气体产生过程,利用宏转录组和宏代谢组学等技术,全面探讨堆肥过程中碳氮转化的微生物学机理。

(3) 当前堆肥添加剂的研究主要关注堆肥过程,对农业废弃物堆肥、还田等全链条的气体排放评估仍较少。同时,外源添加剂对土壤、农业环境等的影响机制以及生态风险仍有待更全面深入地研究。

| [1] |

李瑞婷, 宋国华, 李静, 等. 畜禽粪污资源化利用的现状及问题探讨[J]. 家畜生态学报, 2022, 43(7): 83-87. LI R T, SONG G H, LI J, et al. The status quo and problems of resource utilization of livestock manure[J]. Acta Ecologae Animalis Domastici, 2022, 43(7): 83-87. |

| [2] |

LIU Y, TANG R L, LI L Q, et al. A global meta-analysis of greenhouse gas emissions and carbon and nitrogen losses during livestock manure composting: Influencing factors and mitigation strategies[J]. Science of t he Total Environment, 2023, 885: 163900. DOI:10.1016/j.scitotenv.2023.163900 |

| [3] |

SHAN G C, LI W G, GAO Y J, et al. Additives for reducing nitrogen loss during composting: A review[J]. Journal of Cleaner Production, 2021, 307: 127308. DOI:10.1016/j.jclepro.2021.127308 |

| [4] |

LIU Y, MA R N, WANG J N, et al. Effect of nano zero-valent iron, potassium persulphate, and biochar on maturity and gaseous emissions during multi-material co-composting[J]. Environmental Technology & Innovation, 2023, 32: 103309. |

| [5] |

LUO Y M, LI G X, LUO W H, et al. Effect of phosphogypsum and dicyandiamide as additives on NH3, N2O and CH4 emissions during composting[J]. Jour n al of Environmental Sciences, 2013, 25(7): 1338-1345. |

| [6] |

王义祥, 叶菁, 林怡, 等. 花生壳生物炭用量对猪粪堆肥温室气体和NH3排放的影响[J]. 中国农业大学学报, 2021, 26(6): 114-125. WANG Y X, YE J, LIN Y, et al. Effects of peanut shell biochar on greenhouse gas and NH3 emissions during swine manure composting[J]. Journal of China Agricultural University, 2021, 26(6): 114-125. |

| [7] |

GABHANE J, WILLIAM S P, BIDYADHAR R, et al. Additives aided composting of green waste: Effects on organic matter degradation, compost maturity, and quality of the finished compost[J]. Bioresource Technology, 2012, 114: 382-388. DOI:10.1016/j.biortech.2012.02.040 |

| [8] |

CHEN L, CHEN Y N, LI Y P, et al. Improving the humification by additives during composting: A review[J]. Waste Management, 2023, 158: 93-106. DOI:10.1016/j.wasman.2022.12.040 |

| [9] |

ZHANG Z C, ZHAO Y, YANG T X, et al. Effects of exogenous protein-like precursors on humification process during lignocellulose-like biomass composting: Amino acids as the key linker to promote humification process[J]. Bioresource Technology, 2019, 291: 121882. DOI:10.1016/j.biortech.2019.121882 |

| [10] |

WANG Q, LI R H, CAI H Z, et al. Improving pig manure composting efficiency employing Ca-bentonite[J]. Ecological Engineering, 2016, 87: 157-161. DOI:10.1016/j.ecoleng.2015.11.032 |

| [11] |

闫召伟, 杨菲宇, 高兴祖, 等. 含硫添加剂对猪粪堆肥过程甲烷与臭气排放的影响[J]. 农业环境科学学报, 2021, 40(11): 2448-2455. YAN Z W, YANG F Y, GAO X Z, et al. Effect of sulfur-containing additives on methane and odor emissions during pig manure composting[J]. Journal of Agro-Environment Science, 2021, 40(11): 2448-2455. |

| [12] |

杨燕, 尹子铭, 袁京, 等. 双氰胺和氢醌添加对堆肥温室气体排放的影响[J]. 农业环境科学学报, 2021, 40(11): 2439-2447. YANG Y, YIN Z M, YUAN J, et al. Effects of dicyandiamide and hydroquinone on greenhouse gas emissions during composting[J]. Journal of Agro-Environment Science, 2021, 40(11): 2439-2447. |

| [13] |

HUANG D L, LI T, XU P, et al. Deciphering the Fenton-reaction-aid lignocellulose degradation pattern by Phanerochaete chrysosporium with ferroferric oxide nanomaterials: Enzyme secretion, straw humification and structural alteration[J]. Bioresource Technology, 2019, 276: 335-342. |

| [14] |

LI S X, XU S Q, CHEN S, et al. Carbon-containing additives changes the phosphorus flow by affecting humification and bacterial community during composting[J]. Bioresource Technology, 2023, 379: 129066. |

| [15] |

HE X Q, PENG Z H, ZHU Y X, et al. Wheat straw biochar as an additive in swine manure Composting: An in-depth analysis of mixed material particle characteristics and interface interactions[J]. Waste Management, 2024, 176: 41-51. |

| [16] |

ZHANG W M, YU C X, WANG X J, et al. Additives improved saprotrophic fungi for formation of humic acids in chicken manure and corn Stover mix composting[J]. Bioresource Technology, 2022, 346: 126626. |

| [17] |

余谟鑫, 朱博文, 张书海, 等. 核桃青皮基磁性生物质炭的制备及其对Co2+的吸附性能[J]. 高校化学工程学报, 2022, 36(4): 610-616. YU M X, ZHU B W, ZHANG S H, et al. Synthesis of magnetic biomass carbon from walnut peel and its Co2+ adsorption performance[J]. Journal of Chemical Engineering of Chinese Universities, 2022, 36(4): 610-616. |

| [18] |

FENG M T, WU X Y, QIU X W, et al. Influence of peat and biochar on gas emissions and microbial metabolism during Co-composting of chicken manure and maize straw[J]. Waste and Biomass Valorization, 2023, 14(1): 197-208. |

| [19] |

LIU X Y, ZHANG L. Effects of additives on the co-composting of forest residues with cattle manure[J]. Bioresource Technology, 2023, 368: 128384. |

| [20] |

YU C J, LU Q, FU C, et al. Exploring the internal driving mechanism underlying bacterial community-induced organic component conversion and humus formation during rice straw composting with tricarboxylic acid cycle regulator addition[J]. Bioresource Technology, 2022, 365: 128149. |

| [21] |

ZHENG G R, CHEN A Q, WANG C, et al. Nitrogen retention driven by cooperative succession of bacterial communities through promoting nitrogen fixation and inhibiting denitrification during straw composting with amino acids addition[J]. Environmental Technology & Innovation, 2024, 34: 103584. |

| [22] |

JANG J C, SHIN P K, YOON J S, et al. Glucose effect on the biodegradation of plastics by compost from food garbage[J]. Polymer Degradation and Stability, 2002, 76(1): 155-159. |

| [23] |

李慧, 付亮亮, 杨昊, 等. 以菱镁矿尾矿为脱硫剂的高温烟气脱硫机理及动力学研究[J]. 高校化学工程学报, 2023, 37(6): 1007-1016. LI H, FU L L, YANG H, et al. Mechanism and kinetics of high-temperature flue gas desulfurization with magnesia tailings as a desulfurization sorbent[J]. Journal of Chemical Engineering of Chinese Universities, 2023, 37(6): 1007-1016. |

| [24] |

MAO H, ZHANG H Y, FU Q, et al. Effects of four additives in pig manure composting on greenhouse gas emission reduction and bacterial community change[J]. Bioresource Technology, 2019, 292: 121896. |

| [25] |

ZHENG W, YANG Z M, HUANG L, et al. Roles of organic matter transformation in the bioavailability of Cu and Zn during sepiolite-amended pig manure composting[J]. Journal of Environmental Management, 2022, 314: 115046. |

| [26] |

SOUDEJANI H T, KAZEMIAN H, INGLEZAKIS V J, et al. Application of zeolites in organic waste composting: A review[J]. Biocatalysis and Agricultural Biotechnology, 2019, 22: 101396. |

| [27] |

LI S Y, GU X H, LI H, et al. Effects of phosphorus-containing additives on carbon transformation during pig manure composting[J]. Environmental Technology & Innovation, 2023, 32: 103290. |

| [28] |

LIU Z H, DAI Y, ZHU H X, et al. Effects of additive on formation and electron transfer capacity of humic substances derived from silkworm-excrement compost during composting[J]. Journal of Environmental Management, 2024, 351: 119673. |

| [29] |

ZHANG L X, SHI T, XU Z C, et al. Effect of lime and calcium magnesium phosphate on gaseous emissions, maturity, and bacterial dynamics during food waste composting[J]. Environmental Technology & Innovation, 2023, 32: 103306. |

| [30] |

PAN C N, YANG H Y, GAO W F, et al. Optimization of organic solid waste composting process through iron-related additives: A systematic review[J]. Journal of Environmental Management, 2024, 351: 119952. |

| [31] |

ZHANG L H, ZHU Y, ZHANG J C, et al. Impacts of iron oxide nanoparticles on organic matter degradation and microbial enzyme activities during agricultural waste composting[J]. Waste Management, 2019, 95: 289-297. |

| [32] |

张柯, 闫云涛, 董勇. Fe3+/H2O2类芬顿降解性能及反应机理[J]. 高校化学工程学报, 2022, 36(2): 249-257. ZHANG K, YAN Y T, DONG Y. Degradation performance and reaction mechanism of Fe3+/H2O2 Fenton-like systems[J]. Journal of Chemical Engineering of Chinese Universities, 2022, 36(2): 249-257. |

| [33] |

WU D, REN H, ZHAO Y, et al. Effect of Fenton-like reactions on the hydrolysis efficiency of lignocellulose during rice straw composting based on genomics and metabolomics sequencing[J]. Journal of Cleaner Production, 2023, 396: 136493. |

| [34] |

WEI Y Q, WU D, WEI D, et al. Improved lignocellulose-degrading performance during straw composting from diverse sources with actinomycetes inoculation by regulating the key enzyme activities[J]. Bioresource Technology, 2019, 271: 66-74. |

| [35] |

ZHOU L Y, XIE Y Q, WANG X W, et al. Influence of different microbial inoculants on nitrogen retention and diazotroph community succession during cotton straw composting[J]. Process Safety and Environmental Protection, 2023, 172: 882-893. |

| [36] |

SUN L L, TAO Z D, LIU X C, et al. Effects of phosphate-solubilizing bacteria on phosphorus components, humus and bacterial community metabolism during spent mushroom substrate composting[J]. Environmental Technology & Innovation, 2023, 32: 103341. |

| [37] |

HE Y W, HE Y D, AL-DHABI N A, et al. Effects of exogenous thermophilic bacteria and ripening agent on greenhouse gas emissions, enzyme activity and microbial community during straw composting[J]. Bioresource Technology, 2024, 407: 131114. |

| [38] |

XIE G X, KONG X L, KANG J L, et al. Fungal community succession contributes to product maturity during the co-composting of chicken manure and crop residues[J]. Bioresource Technology, 2021, 328: 124845. |

| [39] |

WU D, WEI Z M, GAO X Z, et al. Reconstruction of core microbes based on producing lignocellulolytic enzymes causing by bacterial inoculation during rice straw composting[J]. Bioresource Technology, 2020, 315: 123849. |

| [40] |

李文玉, 栾亚宁, 孙向阳, 等. 接种外源微生物菌剂对园林废弃物堆肥腐熟的影响[J]. 生态学杂志, 2014, 33(10): 2670-2677. LI W Y, LUAN Y N, SUN X Y, et al. Effects of inoculating microbes on composting of green wastes[J]. Chinese Journal of Ecology, 2014, 33(10): 2670-2677. |

| [41] |

XU Z C, GAO X Z, LI G X, et al. Microbes from mature compost to promote bacterial chemotactic motility via tricarboxylic acid cycle-regulated biochemical metabolisms for enhanced composting performance[J]. Bioresource Technology, 2023, 387: 129633. |

| [42] |

DONG S J, LI R Q, ZHOU K Y, et al. Response of humification process to fungal inoculant in corn straw composting with two different kinds of nitrogen sources[J]. Science of t he Total Environment, 2024, 946: 174461. |

| [43] |

邢睿智, 艾超凡, 王梦怡, 等. 畜禽粪便超高温好氧堆肥工程案例[J]. 农业环境科学学报, 2021, 40(11): 2405-2411. XING R Z, AI C F, WANG M Y, et al. Hyperthermophilic composting of livestock manure: A case study[J]. Journal of Agro-Environment Science, 2021, 40(11): 2405-2411. |

| [44] |

张智, 乔艳, 陈云峰, 等. 不同菌剂对鸡粪堆肥过程中有害气体排放的影响[J]. 中国农业科技导报, 2021, 23(12): 145-150. ZHANG Z, QIAO Y, CHEN Y F, et al. Effects of three microbial agents on harmful gas emission during chicken manure composting[J]. Journal of Agricultural Science and Technology, 2021, 23(12): 145-150. |

| [45] |

WANG S G, ZENG Y. Ammonia emission mitigation in food waste composting: A review[J]. Bioresource Technology, 2018, 248: 13-19. |

| [46] |

穆仕芳, 王洪亮, 王艳, 等. H2O2改性活性炭高效催化转化NO2制NO[J]. 高校化学工程学报, 2017, 38(3): 493-499. MU S F, WANG H L, WANG Y, et al. Highly efficient catalytic conversion of NO2 to NO by H2O2 modified activated carbon[J]. Journal of Chemical Engineering of Chinese Universities, 2017, 38(3): 493-499. |

| [47] |

YANG X Y, DUAN P P, CAO Y B, et al. Mechanisms of mitigating nitrous oxide emission during composting by biochar and calcium carbonate addition[J]. Bioresource Technology, 2023, 388: 129772. |

| [48] |

HUANG D L, GAO L, CHENG M, et al. Carbon and N conservation during composting: A review[J]. Science of t he Total Environment, 2022, 840: 156355. |

| [49] |

杨颂, 李正甲, 杨林颜, 等. CO2甲烷化催化剂的研究进展[J]. 高校化学工程学报, 2023, 37(1): 13-21. YANG S, LI Z J, YANG L Y, et al. Research progress of CO2 methanation catalysts[J]. Journal of Chemical Engineering of Chinese Universities, 2023, 37(1): 13-21. |

| [50] |

GUO H H, GU J, WANG X J, et al. Microbial mechanisms related to the effects of bamboo charcoal and bamboo vinegar on the degradation of organic matter and methane emissions during composting[J]. Environmental Pollution, 2021, 272: 116013. |

| [51] |

JANCZAK D, MALIŃSKA K, CZEKAŁA W, et al. Biochar to reduce ammonia emissions in gaseous and liquid phase during composting of poultry manure with wheat straw[J]. Waste Management, 2017, 66: 36-45. |

| [52] |

YIN Y N, LI M T, TAO X H, et al. Biochar enhanced organic matter transformation during pig manure composting: Roles of the cellulase activity and fungal community[J]. Journal of Environmental Management, 2023, 333: 117464. |

| [53] |

SANCHEZ-MONEDERO M A, CAYUELA M L, ROIG A, et al. Role of biochar as an additive in organic waste composting[J]. Bioresource Technology, 2018, 247: 1155-1164. |

| [54] |

HARTER J, GUZMAN-BUSTAMANTE I, KUEHFUSS S, et al. Gas entrapment and microbial N2O reduction reduce N2O emissions from a biochar-amended sandy clay loam soil[J]. Scientific Reports, 2016, 6: 39574. |

| [55] |

GONG X Q, ZOU L, WANG L, et al. Biochar improves compost humification, maturity and mitigates nitrogen loss during the vermicomposting of cattle manure-maize straw[J]. Journal of Environmental Management, 2023, 325: 116432. |

| [56] |

WANG Q, AWASTHI M K, REN X N, et al. Combining biochar, zeolite and wood vinegar for composting of pig manure: The effect on greenhouse gas emission and nitrogen conservation[J]. Waste Management, 2018, 74: 221-230. |

| [57] |

NIE E Q, GAO D, ZHENG G D. Effects of lactic acid on modulating the ammonia emissions in co-composts of poultry litter with slaughter sludge[J]. Bioresource Technology, 2020, 315: 123812. |

| [58] |

张地方, 袁京, 王国英, 等. 木本泥炭添加比例对猪粪堆肥腐熟度和污染及温室气体排放的影响[J]. 农业工程学报, 2016, 32(增刊2): 233-240. ZHANG D F, YUAN J, WANG G Y, et al. Effects of woody peat addition on maturity and gaseous emissions during pig manure composting[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(Suppl.2): 233-240. |

| [59] |

付祥峰, 刘琪琪, 李恋卿, 等. 生物质炭对猪粪堆肥过程中氮素转化及温室气体排放的影响[J]. 农业环境科学学报, 2017, 36(9): 1893-1900. FU X F, LIU Q Q, LI L Q, et al. Effects of biochar on nitrogen transformation and greenhouse gas emissions during swine manure composting[J]. Journal of Agr o-Environment Science, 2017, 36(9): 1893-1900. |

| [60] |

LIN X, WANG N Y, LI F H, et al. Evaluation of the synergistic effects of biochar and biogas residue on CO2 and CH4 emission, functional genes, and enzyme activity during straw composting[J]. Bioresource Technology, 2022, 360: 127608. |

| [61] |

AGYARKO-MINTAH E, COWIE A, VAN ZWIETEN L, et al. Biochar lowers ammonia emission and improves nitrogen retention in poultry litter composting[J]. Waste Management, 2017, 61: 129-137. |

| [62] |

SÁNCHEZ-GARCÍA M, ALBURQUERQUE J A, SÁNCHEZ-MONEDERO M A, et al. Biochar accelerates organic matter degradation and enhances N mineralisation during composting of poultry manure without a relevant impact on gas emissions[J]. Bioresource Technology, 2015, 192: 272-279. |

| [63] |

MENG L Q, LI W G, ZHANG S M, et al. Improving sewage sludge compost process and quality by carbon sources addition[J]. Scientific Reports, 2021, 11(1): 1319. |

| [64] |

GUO X Y, ZHU Z C, SONG C H, et al. Differences in organic nitrogen transformation during chicken manure composting with the addition of different disaccharides[J]. Science of t he Total Environment, 2023, 888: 164174. |

| [65] |

WU J P, LI M L, WANG Y, et al. Impact of bentonite on greenhouse gas emissions during pig manure composting and its subsequent application[J]. Journal of Environmental Management, 2023, 344: 118453. |

| [66] |

REN X N, WANG Q, LI R H, et al. Effect of clay on greenhouse gas emissions and humification during pig manure composting as supported by spectroscopic evidence[J]. Science of t he Total Environment, 2020, 737: 139712. |

| [67] |

REN X N, WANG Q, AWASTHI M K, et al. Improvement of cleaner composting production by adding Diatomite: From the nitrogen conservation and greenhouse gas emission[J]. Bioresource Technology, 2019, 286: 121377. |

| [68] |

JIANG T, MA X G, YANG J, et al. Effect of different struvite crystallization methods on gaseous emission and the comprehensive comparison during the composting[J]. Bioresource Technology, 2016, 217: 219-226. |

| [69] |

LIU Z Z, YAN Z W, LIU G, et al. Impacts of adding FeSO4 and biochar on nitrogen loss, bacterial community and related functional genes during cattle manure composting[J]. Bioresource Technology, 2023, 379: 129029. |

| [70] |

李丹, 陈豹, 曹云, 等. 二氧化锰对微好氧堆肥腐熟、温室气体及臭气排放的影响[J]. 农业工程学报, 2023, 39(13): 202-212. LI D, CHEN B, CAO Y, et al. Effects of manganese dioxide on composting maturity, greenhouse gas and odor emission of multi-organic solid waste micro-aerobic composting[J]. Transactions of the Chinese Society of Agricultural Engineering, 2023, 39(13): 202-212. |

| [71] |

GENG X Y, YANG H Y, GAO W F, et al. Greenhouse gas emission characteristics during kitchen waste composting with biochar and zeolite addition[J]. Bioresource Technology, 2024, 399: 130575. |

| [72] |

宋修超, 郭德杰, 成卫民, 等. 工厂化条件下外源添加剂对猪粪堆肥过程中NH3和H2S的减排效果[J]. 农业环境科学学报, 2021, 40(9): 2014-2020. SONG X C, GUO D J, CHENG W M, et al. Pilot-scale study on effects of exogenous additives on reducing NH3 and H2S emissions from pig manure compost[J]. Journal of Agro-Environment Science, 2021, 40(9): 2014-2020. |

| [73] |

YANG F, LI G X, SHI H, et al. Effects of phosphogypsum and superphosphate on compost maturity and gaseous emissions during kitchen waste composting[J]. Waste Management, 2015, 36: 70-76. |

| [74] |

SEPEHRI A, SARRAFZADEH M H. Effect of nitrifiers community on fouling mitigation and nitrification efficiency in a membrane bioreactor[J]. Chemical Engineering and Processing-Process Intensification, 2018, 128: 10-18. |

| [75] |

陈文旭, 刘逸飞, 蒋思楠, 等. 微生物菌剂对厨余垃圾堆肥温室气体减排的影响[J]. 农业工程学报, 2022, 38(23): 181-187. CHEN W X, LIU Y F, JIANG S N, et al. Mitigation effects of microbial agents on greenhouse gas emissions from kitchen waste composting[J]. Transactions of the Chinese Society of Agricultural Engineering, 2022, 38(23): 181-187. |

| [76] |

TIAN X R, GAO R Y, LI Y G, et al. Enhancing nitrogen conversion and microbial dynamics in swine manure composting process through inoculation with a microbial consortium[J]. Journal of Cleaner Production, 2023, 423: 138819. |

| [77] |

李舒清, 张镜丹, 纪程, 等. 接种复合菌剂对牛粪好氧堆肥进程及温室气体(CH4和N2O)排放的影响[J]. 南京农业大学学报, 2017, 40(6): 1041-1050. LI S Q, ZHANG J D, JI C, et al. Effects of inoculation of complex microbial inoculants on the process and greenhouse gas (CH4 and N2O) emissions of cattle manure aerobic composting[J]. Journal of Nanjing Agricultural University, 2017, 40(6): 1041-1050. |

| [78] |

JIANG L Y, ZHAO Y T, YAO Y Q, et al. Adding siderophores: A new strategy to reduce greenhouse gas emissions in composting[J]. Bioresource Technology, 2023, 384: 129319. |

| [79] |

WANG Y, BI L L, LIAO Y H, et al. Influence and characteristics of Bacillus stearothermophilus in ammonia reduction during layer manure composting[J]. Ecotoxicology and Environmental Safety, 2019, 180: 80-87. |

| [80] |

XIE K Z, JIA X S, XU P Z, et al. Improved composting of poultry feces via supplementation with ammonia oxidizing archaea[J]. Bioresource Technology, 2012, 120: 70-77. |

| [81] |

YU J, GU J, WANG X J, et al. Effects of inoculation with lignocellulose-degrading microorganisms on nitrogen conversion and denitrifying bacterial community during aerobic composting[J]. Bioresource Technology, 2020, 313: 123664. |

| [82] |

OLIVEIRA L V, HIGARASHI M M, NICOLOSO R S, et al. Use of dicyandiamide to reduce nitrogen loss and nitrous oxide emission during mechanically turned Co-composting of swine slurry with sawdust[J]. Waste and Biomass Valorization, 2020, 11(6): 2567-2579. |

| [83] |

YANG Y, YIN Z M, LI L Q, et al. Effects of dicyandiamide, phosphogypsum and superphosphate on greenhouse gas emissions during pig manure composting[J]. Science of t he Total Environment, 2022, 846: 157487. |

| [84] |

CHEN H Y, AWASTHI S K, LIU T, et al. Effects of microbial culture and chicken manure biochar on compost maturity and greenhouse gas emissions during chicken manure composting[J]. Journal of Hazardous Materials, 2020, 389: 121908. |

| [85] |

HUANG W, SUN X L, SUN H J, et al. Effects of biochar and wood vinegar co-application on composting ammonia and nitrous oxide losses and fertility[J]. Bioresource Technology, 2024, 412: 131388. |